Reimagining your maintenance strategy

By embracing cutting-edge technological solutions such as Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT), you can transition from an outdated and resource-intensive preventive maintenance model to a forward-looking approach. This shift will enable you to redefine your maintenance strategy.

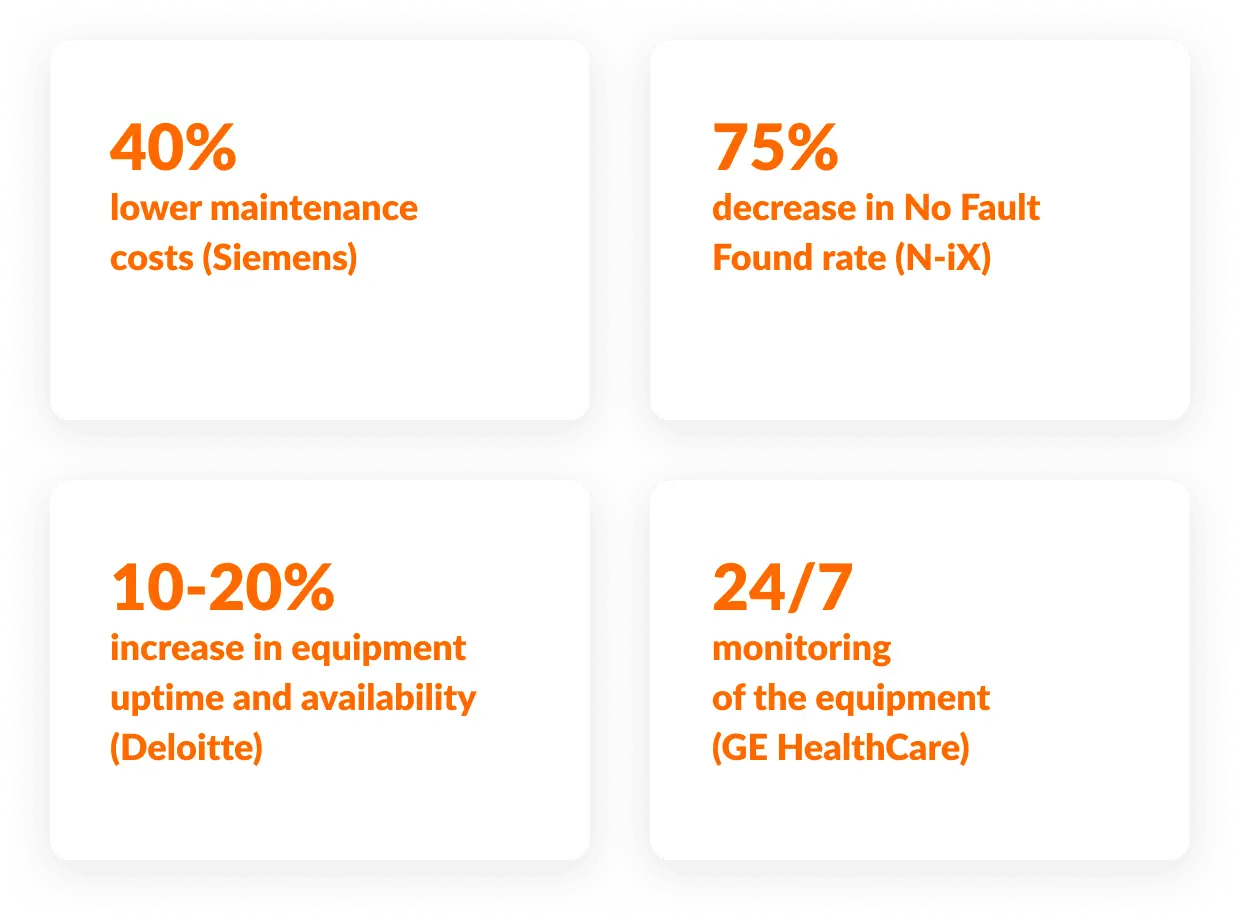

N-iX offers predictive maintenance solutions tailored for various industries, including manufacturing, telecom, logistics, automotive, oil and gas, and others. Our solution will help you save costs, increase efficiency, and improve safety. By leveraging data and advanced analytics, you will be able to refine your maintenance practices and make more informed decisions regarding your equipment and assets.

Predictive maintenance solutions that address your maintenance challenges

Our solution will help you minimize unexpected equipment failures by identifying potential issues before they cause a breakdown.

Properly maintained equipment has a longer lifespan. Our solution helps extend the life of machinery and assets by addressing problems in their early stages.

Fixed maintenance schedules are often inefficient and costly. Meanwhile, maintenance activities based on the actual condition of equipment will result in more efficient use of resources.

Equipment failures can lead to defects in products. Predictive maintenance helps keep consistent quality by preventing machine-related defects.

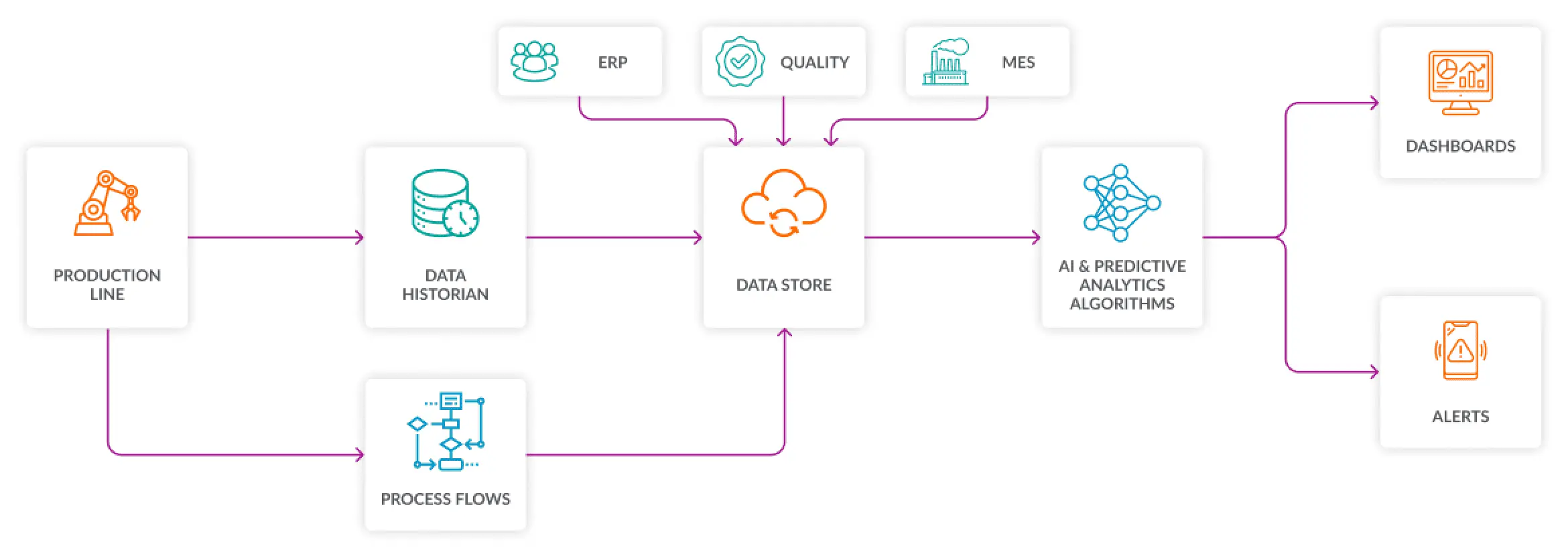

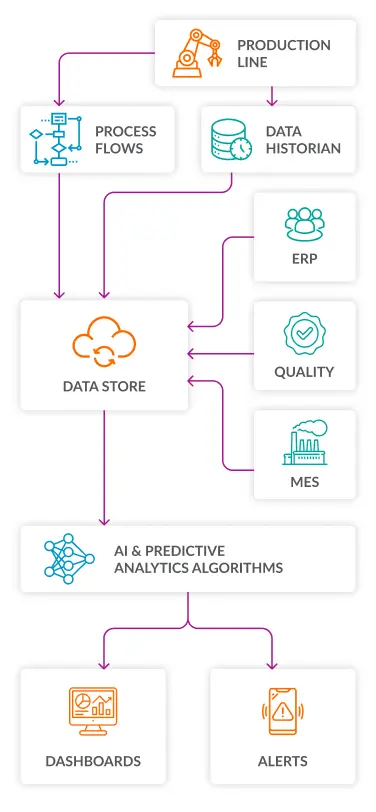

Solution overview: advanced data analytics, easy integration, and effective reporting

1. Data collection

The foundation of predictive maintenance is data. Sensors and data collection tools are essential for gathering real-time information about equipment, including temperature, pressure, vibration, fluid levels, and more.

2. Data storage

Predictive maintenance solutions for manufacturing industry require a robust data storage and management system to store and organize the vast amounts of data generated by sensors and other sources. This often includes data lakes, databases, or cloud-based storage solutions.

3. Data Analytics

Advanced analytics and Machine Learning algorithms are used to analyze historical and real-time data to identify patterns, anomalies, and trends that can predict equipment failures. These algorithms can include regression analysis, neural networks, and clustering techniques.

4. Failure detection and alerts

When a predictive maintenance system identifies a potential issue, it sends alerts to maintenance teams or operators. These alerts can be in the form of notifications or emails. Also, such solutions are able to identify the root causes of failures, as well as asset-specific failures helping you address underlying issues.

5. Feedback loop

The feedback loop is a continuous process that aims to improve equipment reliability and optimize maintenance practices through ongoing data-driven adjustments. It involves data collection, data analysis, generating maintenance forecasts, implementing maintenance actions, outcome monitoring, and feedback itself.

6. Asset health dashboards

User-friendly dashboards provide a visual representation of the health and performance of assets, as well as serve as a data analysis tool. This allows maintenance personnel to assess equipment status and prioritize maintenance tasks quickly.

7. Integration with other systems

Such solutions often integrate with other enterprise systems, such as Enterprise Resource Planning (ERP), CMMS, and enterprise asset management (EAM) solutions to streamline maintenance workflows.

8. Reporting and documentation

The solution generates reports and documentation on performance tracking and maintenance planning, as well as a paper trail needed for regulatory compliance.

Types of data analyzed by our predictive maintenance solution

Data collected with sensors

- temperature

- pressure

- vibration

- humidity

- sound

Machine data

- operating parameters

- error codes

- historical performance and maintenance data

Equipment metadata

- equipment specifications

- manufacturer data

- nameplates

Energy consumption data

- electricity

- gas

- thermal imaging

Smarter machines, smoother operations: the value of predictive maintenance

Save costs

By addressing maintenance issues only when necessary, you can reduce the costs associated with emergency repairs. This leads to cost savings in labor, parts, and equipment replacement.

Make energy usage more efficient

Well-maintained equipment operates more effectively, consuming less energy. This not only reduces energy costs but also contributes to environmental sustainability efforts.

Get valuable business insights

Predictive maintenance generates a wealth of data that can be analyzed to get informed about equipment performance, maintenance trends, and potential process improvements.

Gain competitive advantage

Businesses that implement predictive maintenance can differentiate themselves in the market by offering more reliable services, shorter lead times, and reduced costs compared to competitors relying on traditional reactive maintenance approaches.

Increase production output

By minimizing downtime, reducing unexpected breakdowns, and optimizing equipment reliability, our solution can help you increase production output.

Improve workplace safety

The solution will help with the prevention of accidents, early detection of equipment anomalies, and improved equipment reliability to make the workplace safer.

Optimize inventory management

By reducing the need for spare parts and decreasing emergency maintenance requirements, businesses can manage their inventory more efficiently and reduce associated costs.

Building a custom predictive maintenance solution: How it works

Introductory consultation and workshop

During the initial phase, our team of experts will gather your specific requirements and conduct stakeholder interviews to craft a prototype that precisely aligns with your business needs and requirements.

Data readiness evaluation

Data readiness evaluation is a critical step in any N-iX data-related project. It involves assessing the quality, availability, and suitability of your data that will be used for analysis and decision-making.

PoC development

Next, we will dedicate two weeks to design and create a functional prototype. This prototype will be crafted based on the insights and data gathered during our earlier stages. We will then present the PoC to your stakeholders for their evaluation and testing.

Full-scale solution development

Over the following 3+ months, N-iX engineers will develop a solution, providing support throughout the journey and taking full responsibility for the successful implementation up to the solution's launch.

Scaling to all your assets

In 6 months, we can scale our solution for your whole production process to identify and rectify bottlenecks and malfunctions, thereby enhancing overall productivity and resource utilization.

Contact us

Drop a message to our team to see how we can help

Trusted by

Industry recognition